Self tapping screws are a common type of fastener used in a wide range of applications. They can be used to screw into a variety of materials, including metal and plastic.

They can be either sharp or blunt tipped. Sharp tipped self tapping screws are typically used for drilling into soft materials, such as wood or plastic without having to drill a pilot hole.

Types

Self tapping screws are available in a variety of types. Each type is designed to work for different substrates, materials and applications.

Thread-forming (displaces material) or thread-cutting (cuts away material) screws are the most common types of self tapping screw. They are best for thin and soft substrates such as wood, soft plastics, thinner sheet metals and non-ferrous metals.

Most of these screws feature a sharp tip on the head that combines the fastener installation and drilling process into one step. This makes them a popular choice for applications that involve hard substrates, like assembly lines and carpentry.

Materials

Self tapping screws are used in a variety of applications. They can be found in construction, power boxes, municipal works, agriculture and more.

They are commonly made from metal but can also be manufactured in plastic. The performance of a screw joint depends on a number of factors, including its material type and properties.

The ability to tap into a substrate is most often determined by the gap in the continuity of the thread. Depending on the material, this can be achieved by a point that taper to a gimlet point, or by cutting a hole.

Heads

The heads of self tapping screws are as varied as the materials they are designed to bind together. The hex washer head, for instance, is commonly found on the heaviest fasteners.

A flathead, a bugle, a modified truss and a pancake are just some of the styles available to choose from. The flathead is the best choice for attaching wood to metal studs while the modified truss and pancake are used by drywall contractors to secure plasterboard.

Choosing the right screw for your application can be challenging. However, with a little knowledge and research, you can find the perfect fastener to meet your needs. From there, you can make informed decisions that will increase your productivity and save you time in the long run!

Shanks

A self tapping screw is a type of fastener that produces its own threads during installation. This eliminates the need to drill a pilot hole before driving in a screw.

They are available with many different head types including round head, hex, flat head and truss head. They can also be used with a variety of tools such as hand and electric screwdrivers, wrenches, Torx keys, Allen keys and security tools.

They are usually used in metal and wood, however they can be used in concrete as well. They are able to withstand heat and stress, so they are often used in the construction industry for structural connections and building projects.

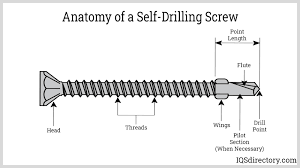

Points

Self tapping screws are a type of thread-cutting screw that can tap its own hole when driven into softer materials. These types of screws are a great option for those who need to secure wood, metal and bricks together without using a nut.

They come in a variety of shapes and have different tip types. Some of them are blunt nose or flat-ended, while others have a pointed nose.

Regardless of the point type, it is essential to choose the correct size self tapping screw that will fit your needs. If you use the wrong size, you may experience thread stripping and it could also cause damage to your material. It is best to take your time and find the right self tapping screw for your application.